Services

ENGINEERING

Engineering Excellence

Efficient and reliable bulk materials handling equipment and systems rely on comprehensive know-how and flawless execution of relevant engineering disciplines. Our fully integrated multidisciplinary engineering team prides itself on having in-depth understanding of your unique needs and ability to develop truly optimized solutions.

Conceptual Design

The design concept has a major impact on CAPEX, but perhaps more importantly, lasting impact on your operations and OPEX. Decisions leading to suboptimal outcomes can be very costly and affect not only

the direct cost and operation of equipment, but often more significantly, related infrastructure costs. Our team of subject matter experts

carefully evaluates multiple options during conceptual stage using first principles approach, while employing best practices from operations

worldwide and continuously assessing all commercial aspects in a trade-off format. The result is a fully optimized solution to your unique

bulk materials handling challenges.

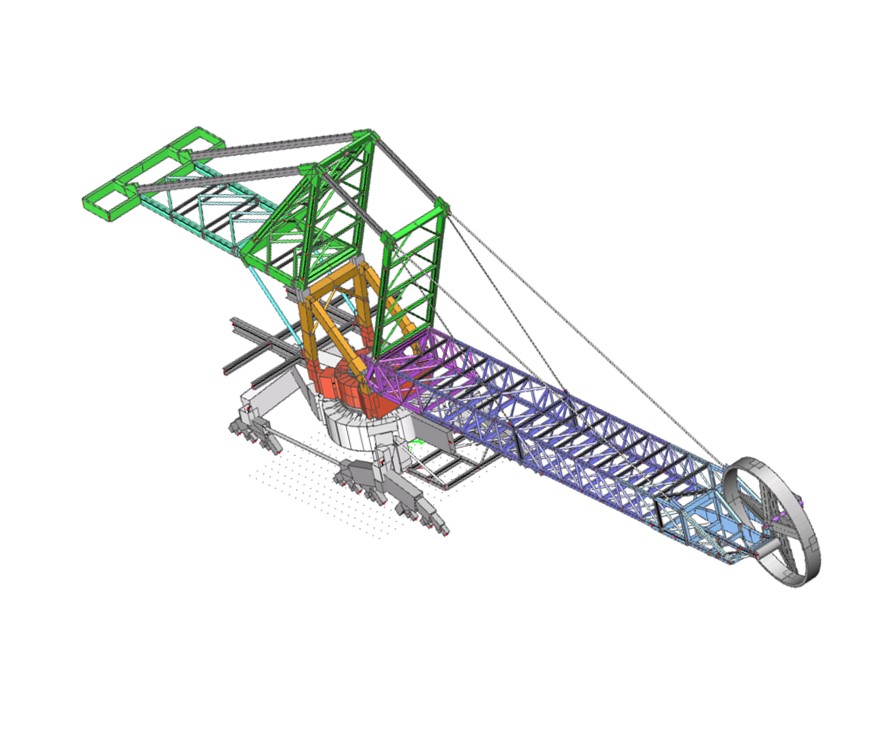

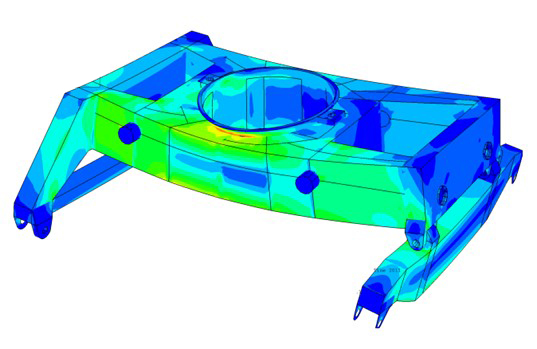

Structural Design

Steel structure is the basic skeleton of bulk materials handling equipment and is therefore the most important component of these complex

machines. Our structural engineers consider all conditions specific to

your applications (such as codes and standards, environmental factors, and required service life) and utilize state-of-the-art engineering methods and software to develop the lightest possible reliable steel structures, with superior structural strength, integrity, stability, and fatigue life.

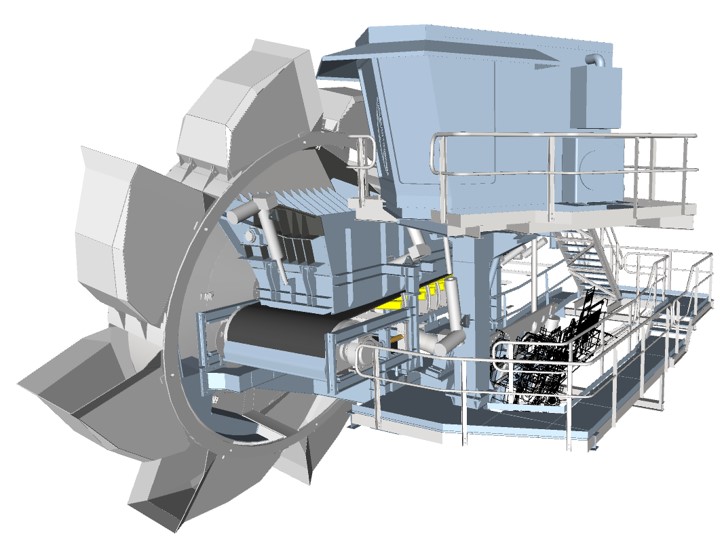

Mechanical Design

Closely integrated with the structural design, mechanical systems on bulk handling machines drive various machine motions. Whether it is drives, rotating components, or hydraulic systems, we take great care in our design to include suitable redundancies and select superior components, all to ensure uninterrupted service and minimal breakdowns.

EI&C Design

Much like the connection between structural and mechanical design, mechanical and electrical, instrumentation, and control (EI&C) design are closely related. Our basic focus is to produce a simple design with a

minimal amount of equipment, cables, instruments, switches, and similar, without sacrificing machine’s functionality. For clients who require greater level of automation, we develop more advanced EI&C systems,

including fully autonomous operation with remote monitoring.

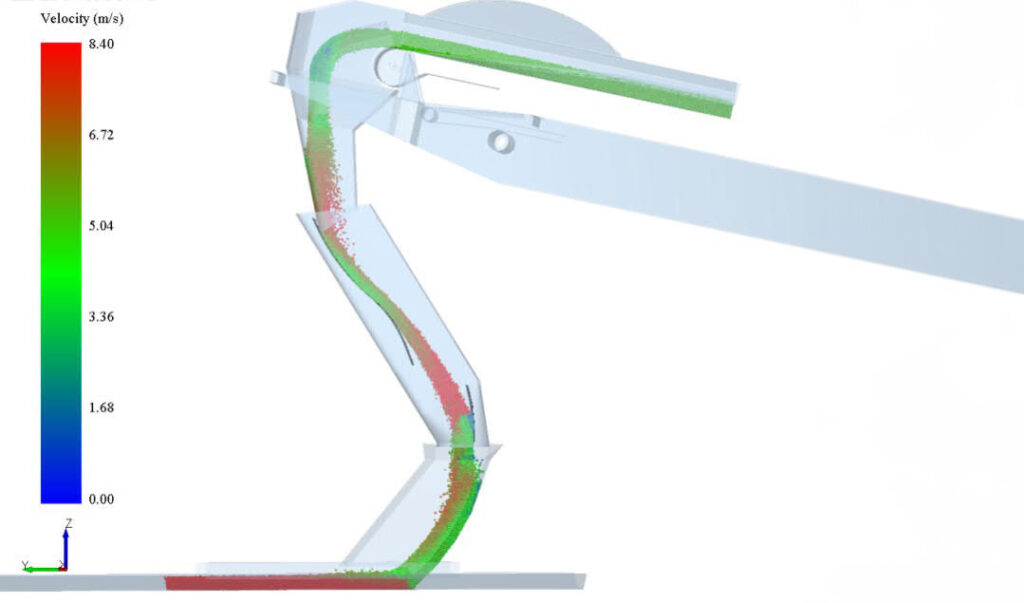

Flow Analysis

Reliable and continuous operation of bulk materials equipment demands that specific attention be given to material flow through feed, transfer, and discharge points. Improper material flow can lead to excessive spillage, major disruptions, unnecessary maintenance, safety

risks, and premature wear or failure of components. We utilize the latest Discrete Element Modeling (DEM) software to simulate flow of material and optimize chute design. For critical applications, difficult transfers, and varying material properties, we go a step further and perform bench tests with scaled down models of transfer points and

actual bulk samples to “calibrate” our DEM models and guarantee real world conditions.